Why Choose Us?

Advanced Equipment

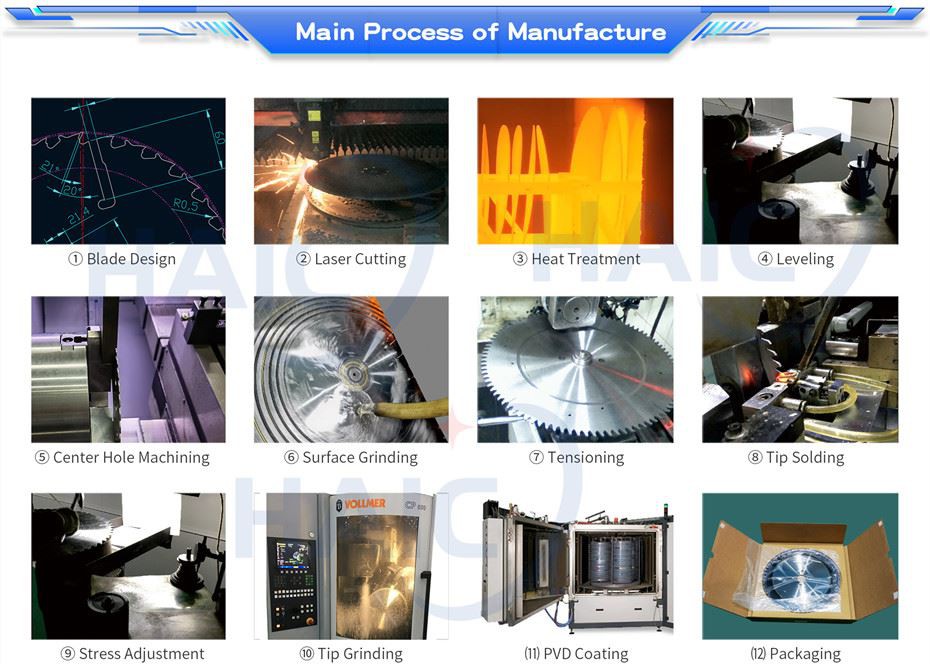

We have a complete set of imported production equipments from Europe and Japan, including laser cutting, heat treatment, tensioning, tip soldering, tip grinding and inspection, etc.

Rich Experience

With over 20 years of experience on cutting tools, fully familiar with various cutting tools, owning TCT circular saw blades, cold saw blades, HSS sawblades and PCD diamond saw blades to meet various requirement of materials being cut.

Production Market

Thanks to our customers' trust and support, up to now, besides more than 200 customers in China, we also have established stable business relations with more than 30 foreign dealers from Europe, South America and Asia.

Customer Service

We can help users at any time to analyze the problems they are facing and provide the best solution. We are also very pleased to cooperate with customers on product LOGO, packaging, transportation, samples and others.

What is Woodworking Saw Blade?

Woodworking saw blade of blade is also called TCT saw blade. Carbide-tipped saw blades are widely used to cut wood, plywood, laminated board, plastic, glass, aluminum and some other metals. Solid-carbide saw blades. The whole saw blade is made of tungsten carbide.

Woodworking Saw Blade is one kind of the most widely used cutting tools of circular saws. It is widely used in log processing, furniture and flooring manufacturing, and home DIY activities.

According to the different cutting objects, woodworking saw blade can be divided into two categories: solid wood cutting saw blade and wood-based panel cutting saw blade. According to the different cutting methods, it is also divided into ripping saw blade, crosscut saw blade, multi-ripping saw blade, trimming saw blade, table saw blade, electronic sizing saw blade and scoring cut saw blade, etc.

Since the use of woodworking saw blade is closely related to the category of cutting material, the dry-wet characteristics of soft and hard, the size of cutting material and cutting equipment, etc., the optimal effect of saw blade products can only be achieved by targeted design according to specific conditions.

With more than 20 years of experience in design, production and service, and strong technical support from Japanese customers, HAIC can provide the best customized woodworking saw blade products according to customers' specific cutting requirements. From the body strength of the saw blade, the tensioning treatment, the kind of cemented carbide, tooth type, cutting angle and other details to ensure that the product performance to meet customer expectations.

●Create faster and more accurate cutss

Compared to a jigsaw, the woodworking saw blade can cut much faster. Furthermore, your work is more visible, so following a line is easier. A woodworking saw blade also allows you to cut through thicker material with straighter cuts.

● Minimize waste when using a bandsaw

Compared to other saws (e.g., chainsaw and table saw), the bandsaw blade is narrower. As a result the thickness of the cut is smaller. This results in less sawdust and helps to minimize waste material. A woodworking saw blade also allows you to re-saw lumber. This is the process of cutting a board into thinner pieces. By re-sawing lumber, you can create multiple thin boards from one larger thicker piece of wood.

● Woodworking saw blade are one of the safest tools

Bandsaws are low impact and friendly to use. The bandsaw blade cuts in a downward direction which helps keep the workpiece solidly on the table as you make the cut. This helps minimize the risk of kickback and injury.

● Woodworking saw blade provide precise cutting

The band saw is an ideal tool if you want precise cutting. The thin blades allow you to have total control over the saw. Other features like dual-bearing blades and blade tracking allow for fine and accurate cuts for the best finish.

● The woodworking saw blade is a flexible tool

Besides cutting lumber, you can cut meat, and even metal with bandsaw. You can also purchase thicker blades for heavy cutting and thinner blades for delicate and precise cuts.

Performance of Woodworking Saw Blade

01

Woodworking saw blades with more teeth cut slower, but leave a cleaner cut.

02

Woodworking saw blades with fewer teeth cut faster but tend to leave a rougher surface.

03

Woodworking saw blades designed for ripping solid wood have fewer teeth as more space is needed between them to clear the longer, stringy chips that are generated.

04

Woodworking saw blades for crosscutting have many teeth to create a smooth, clean cut across the grain.

Classification of Woodworking Saw Blade

Tct circular saw blades

Tct circular saw blades for cutting of wood, acrylic, non-ferrous metal and steel.

Cold saw blades

Cold saw blades for cutting of solid steel and steel tubes.

Hss circular saw blades

Hss circular saw blades for cutting of metal and stainless steel material.

Diamond saw blades

Diamond saw blades for wood composite, aluminium and ceramic materials, etc.

Factors to Consider When Woodworking Saw Blade

When choosing a blade, here are a few things to consider

Diameter

This is measured from the furthest edge of one tip to the furthest edge of the tip directly opposite. Use the saw diameter the machine was designed for. Even if the material being cut doesn't require the depth of cut you will get from the proper size blade, you want the rim speed attained by a full diameter blade.

Tooth count

The basic rule is the more teeth the finer the cut, but you also have to consider the thickness of the cut and the feed rate. Fine tooth saws tend to leave a smoother finish because each tooth takes a smaller bite, however, if the material is too thick, or if it is being fed at a high rate, the gullet capacity of fine-tooth blades is too small.

Tooth style

These generally fall into three categories: Square Top style-rip saw, for downgrain cutting of solid wood; Alternate Top Bevel style-cut-off saw, for crossgrain cutting; and Triple Chip style-primarily for composite panel.

Our Factory

Hangzhou Accurate International Co., Ltd. (HAIC for short) is a company specializing in the development, production and sales of circular saw blades. HAIC operates and manages in full accordance with Japan standards JIS B4805, Germany Din54 and D8033of circular sawblades, approved by SGS and ISO9001. With over 20 years of experience on cutting tools, HAIC is fully familiar with various cutting tools, owning TCT circular saw blades, cold saw blades, HSS sawblades and PCD diamond saw blades to meet various requirement of materials being cut.

Production Equipment

We always believe and insist that high precision and reliable equipment with good maintenance is the basis of producing quality products.

Our Certificate

We are a national high-tech enterprise and has passed the ISO9001 quality management system certification. In addition, due to our technical team's continuous innovation and supports from our Japanese technicians, we has obtained a total of 15 patents for inventions and utility models.

Frequently Asked Questions

Q: What is the purpose of a saw blade?

Q: What saw blade makes the smoothest cut?

Q: What kind of saw is best for woodworking?

Q: What is the strongest type of saw blade?

Q: How many teeth is best for cutting wood?

Q: Can I use circular saw blade on table saw?

Q: What blades are generally used for woodworking?

Q: What saw blades are most commonly used by woodworkers in their work?

Q: What material Cannot be cut on the table saw?

Q: What saw is best for cutting plywood?

Q: What are different blades for on table saw?

Q: What is a sawblade used for?

Q: What is the difference between a wood blade and a metal blade?

Q: Is it OK to cut wood with a metal blade?

Q: What is the difference between saw blades?

Q: What kind of blade to use for wood table saw?

Q: Will a wood saw blade cut metal?

Q: What is the three tooth rule for sawing?

Q: Which saw blade makes the smoothest cut?

Q: Why is the number of teeth on a saw blade important?

We're professional woodworking saw blade manufacturers and suppliers in China, specialized in providing high quality customized products. We warmly welcome you to wholesale high-grade woodworking saw blade at competitive price from our factory.

cnc wood router machine